Sustainable protein concentrates from dry fractionation

As the world’s population grows and the demand for protein increases, there is a global trend toward plant-based proteins and a corresponding demand for specialty flours. At the same time, there is a growing ask for resource-conserving and natural processing options.

Our answer is protein shifting.

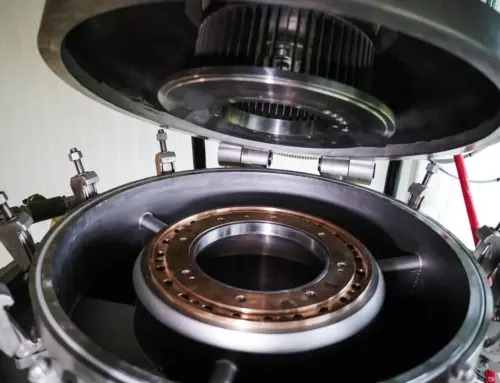

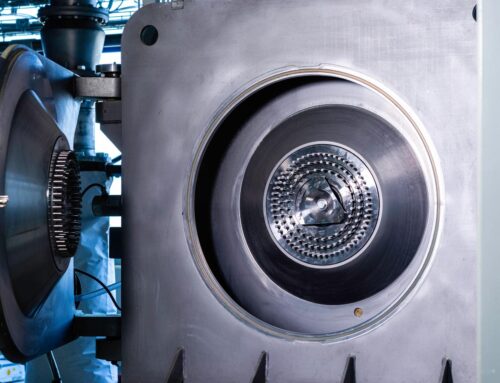

Protein shifting (also called dry fractionation) allows protein-rich crops such as peas and beans to be separated into two components: a protein-rich fraction and a starch-rich fraction.

The major advantage of this method is that the entire process is carried out without the use of water or chemicals, making it a cost-, environment- and resource-efficient alternative to the extraction of plant proteins.

However, the process is not entirely simple. Dry fractionation relies on mechanical disruption of the cells by grinding, to separate the starch and protein components, which are then separated into fractions by air classification. In order to achieve this, an optimum degree of comminution must first be achieved, as the starch particles must not be damaged during the intensive grinding process. Otherwise, subsequent separation of the coarser starch particles from the finer protein particles will not be possible. Control of the process is therefore essential to achieve sharp separation of the fractions and an optimum balance between protein content and yield.

Depending on the product and yield, flours with up to 75% protein content can be produced. Dry fractionation is therefore an efficient and, above all, very sustainable alternative for obtaining vegetable proteins and starches for human nutrition and for use as high-quality animal feed.

Leave A Comment