Milling technology in the food industry

In the food industry, the processing of powders plays a crucial role. Beverage applications, baking ingredients and food supplements all require high-quality powders that are ground precisely and reduced to defined particle sizes in order to fulfil the desired quality standards. But how exactly do these processes work and which technologies are used? In this article, we provide an overview of the key technologies used in grinding and micronising, and show how Heiss MSP impresses with precision and technology.

The importance of grinding and micronising cannot be overstated:

- Uniform particle sizes are essential for optimal processing and dosing.

- Finer particles offer numerous advantages, such as increased water binding, better solubility, and improved texture or creaminess.

- Increased bioavailability is particularly important for dietary supplements and functional foods.

- High-precision control is perfect for applications where consistency and homogeneity are essential.

The technological principles of grinding

Depending on the material properties and the desired particle size, different grinding technologies are employed:

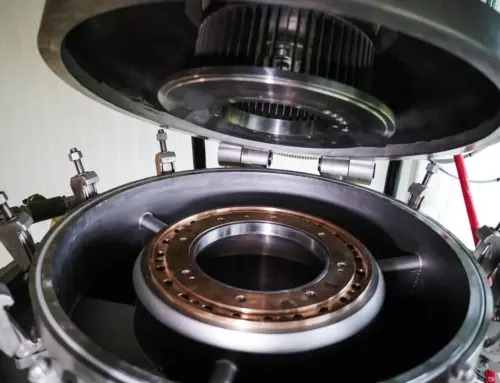

- Pin mills: These are a highly versatile solution that can be used for a variety of applications, and are capable of producing fine and uniform particle sizes.

- Classifier mills: These mills offer a combination of size reduction and classification, making them ideal for precise particle size distribution requirements.

- Whirlwind mills: They are particularly efficient when processing heat-sensitive, fibrous products.

- Jet mills: These mills work with high precision, making them ideal for sensitive products and extremely fine results.

The advantages of working with Heiss MSP

As a contract service provider for companies in the food industry, we offer flexible production capacities that can be called up at short notice, thus seamlessly integrating into our customers’ value chains, who benefit from our expertise.

- State-of-the-art technologies: Precise, efficient machines for size reduction ensure excellent results.

- Customised solutions: Every customer receives a customised concept, adapted to their requirements.

- Flexibility: Whether small batches or large-scale production, we have the capacity to meet every production requirement.

- Quality assurance: Our processes are certified to the highest standards, ensuring end products that are safe and of the highest quality.

Precision and innovation go hand in hand

Milling or micronisation is an essential part of food production, requiring high-quality technology and expertise. At Heiss MSP, we integrate technological advancement with agility to deliver the ideal solution for every challenge. Our goal is to provide you with the peace of mind to focus on your core business. To learn more about our services, please click here to access the contact form.

Leave A Comment